The team behind igus:bike – Freewheel

Loud enough? Or would you prefer it quiet? This is where opinions differ. What one person finds cool, might bother the next. Whereas … if you hear it, it’s also a safety aspect, because you are immediately noticed when you approach a person. What is it about? About the freewheel!

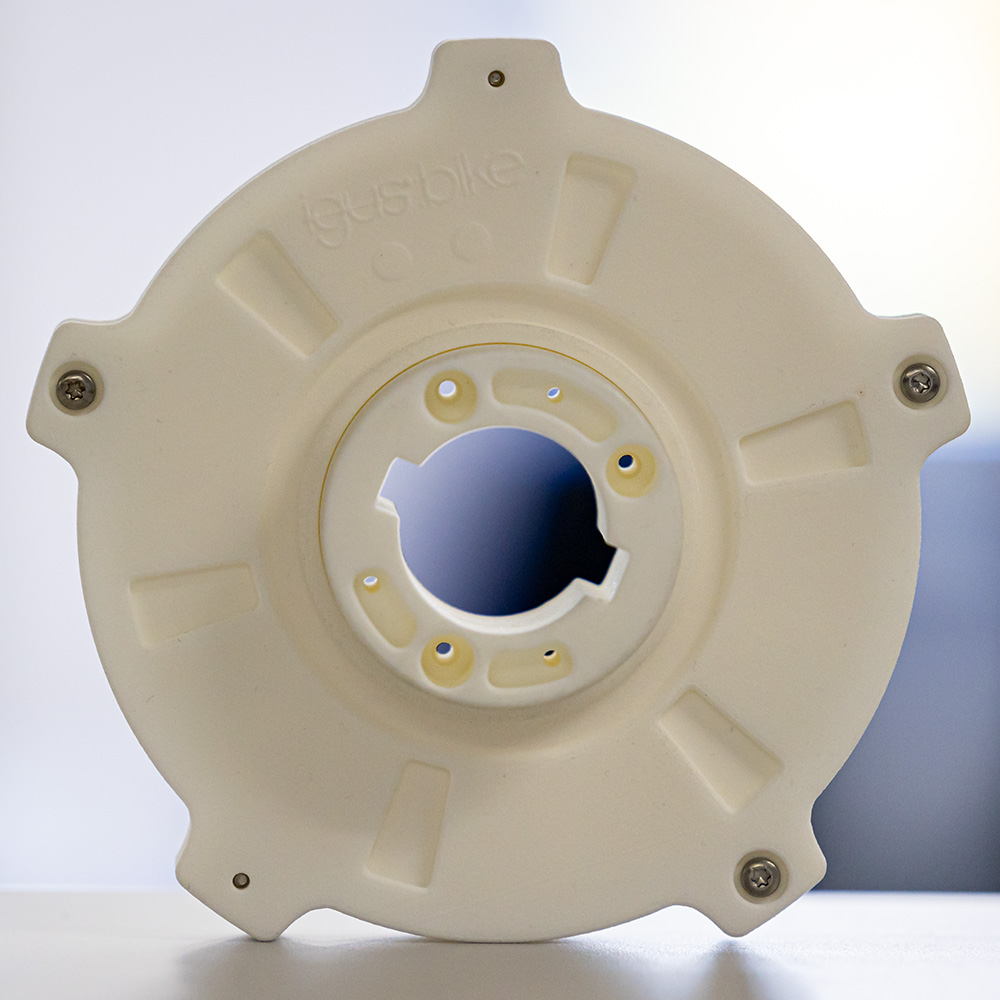

Developer Georg with a freewheel prototype

With the igus:bike, it is quite loud when unassembled. However, developer Georg credibly assures that it is much quieter later on in the bike. The great advantages of the freewheel: it does not rust, runs without lubrication and is maintenance-free! And why? Because it consists entirely of high-performance plastics from igus! To come back to the developer, Georg has been working in the development department at igus for 16 years, and normally he deals with e-chain systems. But of course he made an exception for the igus:bike.

First, let’s clarify the basic questions: what exactly does a freewheel do and where is it installed on the bike? The “what” is quite simple, the freewheel decouples the drive from the turning wheel. When you stop pedalling, the wheels keep turning, but the cranks stop moving. Without a freewheel you would have to keep pedalling because the cranks keep turning. The “where” is actually quite simple: on the hub of the rear wheel.

However, Shimano moved the freewheel to the front of the crank in the 70s with the FFS (Front Freewheel System). And trial bikers also often use this freewheel variant to have more freedom to do their stunts. But what are the advantages if the freewheel is in the crank? Quite simply, the entire drive continues to rotate except for the crank, you can shift gears without having to pedal. But how is it now with the igus:bike? There, the freewheel is placed between the crank and the planetary gear. And for quite pragmatic reasons: there was no more room at the rear wheel!

The latest prototype version of the freewheel

This is what the freewheel of an older prototype sounds like

The freewheel of the igus:bike has gone through the classic development stages. First, a smaller freewheel was developed to get to know the demands on the material and the technology itself. In order to be able to transmit the forces that occur, it first became significantly larger.

The mechanism that was first attached on the outside, was moved inside to be better protected. After various tests, the points with peak loads emerged so that other areas could be slimmed down or even omitted – after all, the freewheel should fit into the bicycle frame!

The current version is therefore again smaller and lighter than the prototypes before it. As an e-bike version of the igus:bike is also planned for the future, Georg knows that the freewheel of these bikes will be subjected to significantly higher forces. So the development of the plastic bicycle remains exciting!

Developer Georg explains the freewheel